high-filled phosphogypsum hollow sheet extrusion line turns chemical solid waste into "green gold".

Date:2025/7/26 14:23:53 / Read: / Source:This website

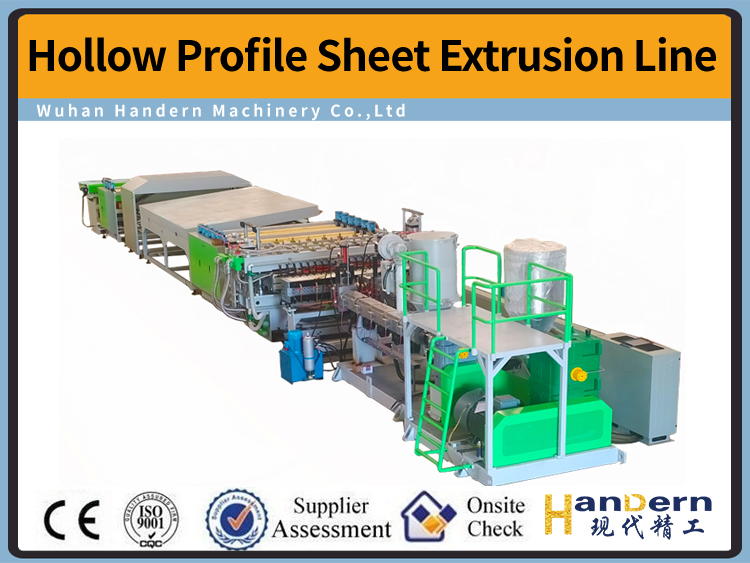

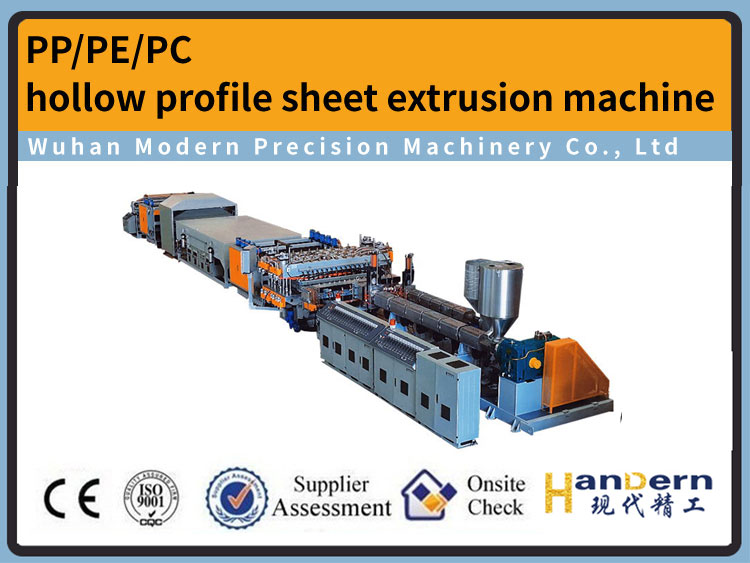

The 4th "National Industrial By-product Gypsum and New Technology and Equipment Exchange Conference for Comprehensive Utilization of Phosphorus Titanium Gypsum" attracted industry elites from all over the world. Handern Machinery showed the participants the phosphogypsum hollow sheet extrusion line, which can be filled up to 70%, while solving the problem of industrial solid waste and turning chemical solid waste into "green gold".

At the same time, Handern Machinery obtained the "2025 Industrial By-product Gypsum Resource Technology for Industrial Application of High-filled Phosphorus Gypsum Environmentally Friendly Moisture-proof Packaging Materials" Excellent Case Certificate, marking that the phosphogypsum hollow sheet extrusion line technology has officially obtained national authoritative recognition.

Handern Machinery has achieved a phosphogypsum addition ratio of over 70% through original modification technology, while overcoming the two bottlenecks of strength and moisture resistance. Its core process is to convert phosphogypsum into anhydrous gypsum, and after precision grinding and activation modification, it becomes a high-performance filler. This technical path coincides with the exploration of Guizhou Phosphorus Chemical Group and has reached in-depth cooperation. The group has built a 300,000 tons/year anhydrous gypsum production line, which improves the water resistance and wear resistance of the material through high-temperature calcination. Handern Machinery has gone a step further and combined modified phosphogypsum with polymer materials to create a new type of packaging material with excellent performance.

The performance comparison of hollow boards extruded by the phosphogypsum hollow sheet extrusion line is remarkable: compared with ordinary cartons, phosphogypsum packaging boxes have significant waterproof and moisture-proof capabilities, and the compressive strength is increased by more than 30%, which is suitable for high-end scenarios such as cold chain transportation and precision instruments. In terms of environmental benefits, each ton of phosphogypsum can replace 1.3 tons of pulp, greatly reducing deforestation and papermaking pollution.

The benefits of the phosphogypsum hollow sheet extrusion line are clearly visible: The cost of raw materials has been reduced by 30%, and the competitiveness will be further enhanced after scale-up. The product line has been expanded to more than ten categories such as municipal pipes, communication equipment, and degradable ground film. A closed loop of "waste residue-material-application" has been established with leading phosphate fertilizer companies to achieve resource recycling. What is more noteworthy is that the project has been applied for the Hubei Provincial (China) Green Manufacturing Special Project and is expected to be included in the National Resource Comprehensive Utilization Promotion Catalog. Policy support will accelerate the industrialization process.

If you are interested in our high-filled phosphogypsum hollow sheet extrusion line turns chemical solid waste into "green gold". , please fill out the following form and we will contact you as soon as possible.

Author:admin