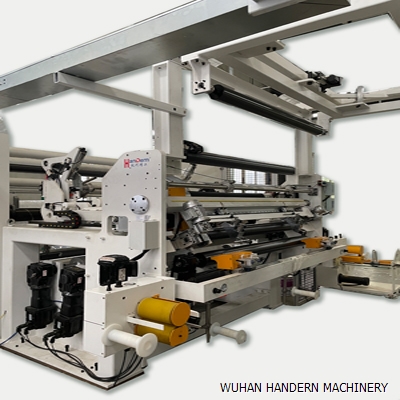

Lines for LiBS film Extrusion lines for separator film in Li-ion batteries

Date:2023/2/1 15:28:40 / Read: / Source:This website

Lines for LiBS film

Extrusion lines for separator film in

Li-ion batteries.

From consumer electronics to electric bikes and cars to stationary energy storage systems:

Today, powerful and long-lasting Li-ion batteries are a key-driver of technical innovation. One of the most important part of a Li-ion battery is the separator. It is a membrane separating the anode and the cathode inside the battery to prevent short circuits and to allow the free transmission of lithium ions.

For meeting highest technical requirements

|

Excellent chemical and thermal stability. Beside a porosity of more than 40 percent and a uniform pore size, separator film musthave excellent properties concerning chemical and thermal stability, tensile strength,low shrinkage and thickness (dimensional strength). To reach these properties, we delivers extrusion lines working on a dry process basis.Compared to separators produced in a wet process, the pore structure of separators produced in a dry process is more open and consistent – and therefore these Li-ion battery separator films are better suitable for higher power density. |

|

||

|

Eco-friendly – very low consumption of raw materials Due to the advantages of the dry production technology, ours extrusion lines for separator film work very cost efficient and eco-friendly. Compared with the more complex wet process, it is not necessary to use solvents to excavate the low-molecular material. Our production line can produce single-layer or three-layer PP or PE based diaphragms, which have perfect product quality and are very suitable for subsequent processing. |

||

If you are interested in our Lines for LiBS film Extrusion lines for separator film in Li-ion batteries , please fill out the following form and we will contact you as soon as possible.

Author:admin