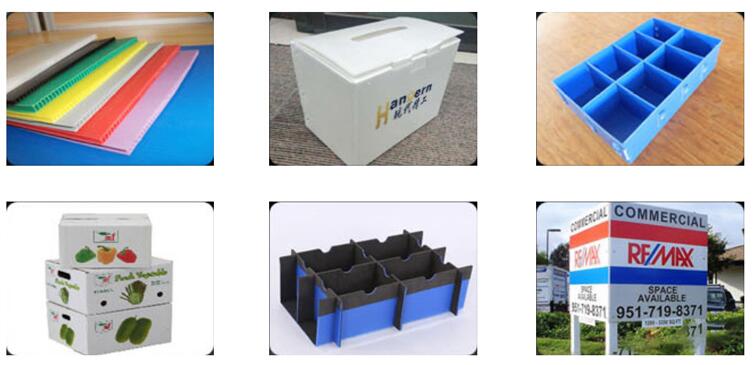

The extrusion line for hollow sheet is a machine used for manufacturing hollow sheets. It is composed of a granule hopper, an extruder, a control console, a screen changer, a mold, a vacuum sizing table, a chiller, a first tractor, a dryer, a second tractor and a plate shearing machine.

The extrusion line for hollow sheet can conduct precise processing according to the batching formula, and can also extrude hollow sheets of different thicknesses and shapes through adjusting the parameters of the mold.

Contact US

Wuhan Handern Machinery Co.,Ltd

Wuhan Handern Machinery Co.,Ltd