About Wuhan Handern Machinery Co.,Ltd.

Wuhan Handern Machinery Co., Ltd. is a leading domestic provider of polymer material extrusion equipment and system solutions and a national-level specialized and new "little giant" enterprise. The company's equipment products are widely used in the production and processing fields of new environmentally friendly packaging materials and high-end functional films. It has leading extrusion equipment and system solutions in many application scenarios, filling the domestic gap and realizing the domestic replacement of high-end equipment.

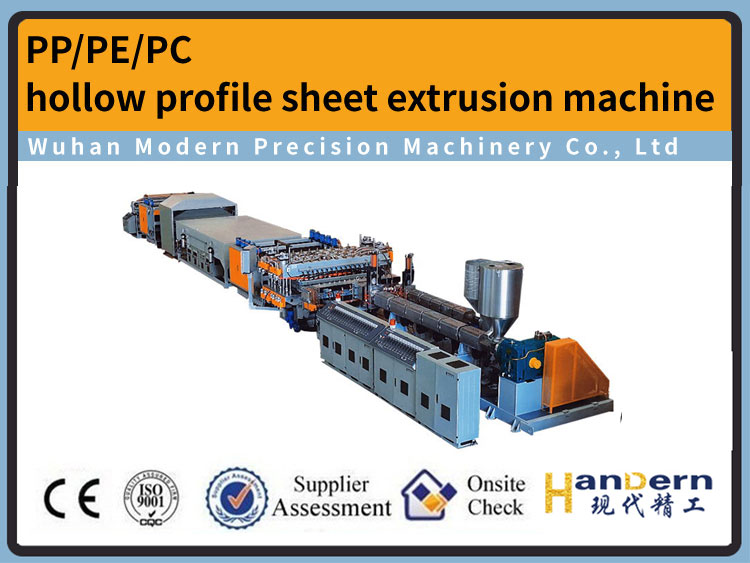

The company's hollow plate equipment exports to more than 20 countries and regions around the world, and its shipments have been ranked first for more than ten consecutive years. It has pioneered one-step manufacturing technology in the world, mastered the manufacturing processes of hollow plates such as high-filled phosphogypsum and fly ash, opened up a new scenario for green application of industrial solid waste, solved major national environmental problems, and delivered the first one-step phosphogypsum hollow plate production line to Guizhou Phosphate Group. The company is a leading domestic dry-process lithium battery separator production equipment enterprise, and the only domestic company with the ability to deliver the entire production line of dry-process lithium battery separator. The downstream terminal applications cover industry leaders such as BYD. The company's semi-solid lithium battery electrolyte membrane, polyimide (PI) membrane, ultra-thin composite fluid collection membrane and other high-end functional film equipment have been delivered to customers one after another.

The company insists on R&D drive and is deeply engaged in the field of polymer extrusion equipment. It has successively established the "Hubei Engineering Research Center for Biomedical and Protective Materials" with Huazhong University of Science and Technology, and jointly established the "Popylmer Intelligent Manufacturing Equipment R&D Center" with South China University of Technology. Relying on the team of Academician Qu Jinping, it has jointly carried out a number of technical development cooperation in the cutting-edge fields of polymer material forming and processing engineering, and is committed to promoting the development of domestic polymer intelligent manufacturing equipment and the process of domestic high-end equipment. The "Key Technique for Strengthening the Process of Polymer Materials Processing" jointly developed by the company, together with Huazhong University of Science and Technology and South China University of Technology, has successfully passed the scientific and technological achievements appraisal organized by the China Plastic Machinery Industry Association. The expert group unanimously believes that the relevant achievements are international firsts and are major innovations in the field of polymer and composite materials processing at home and abroad, and are at the international leading level.